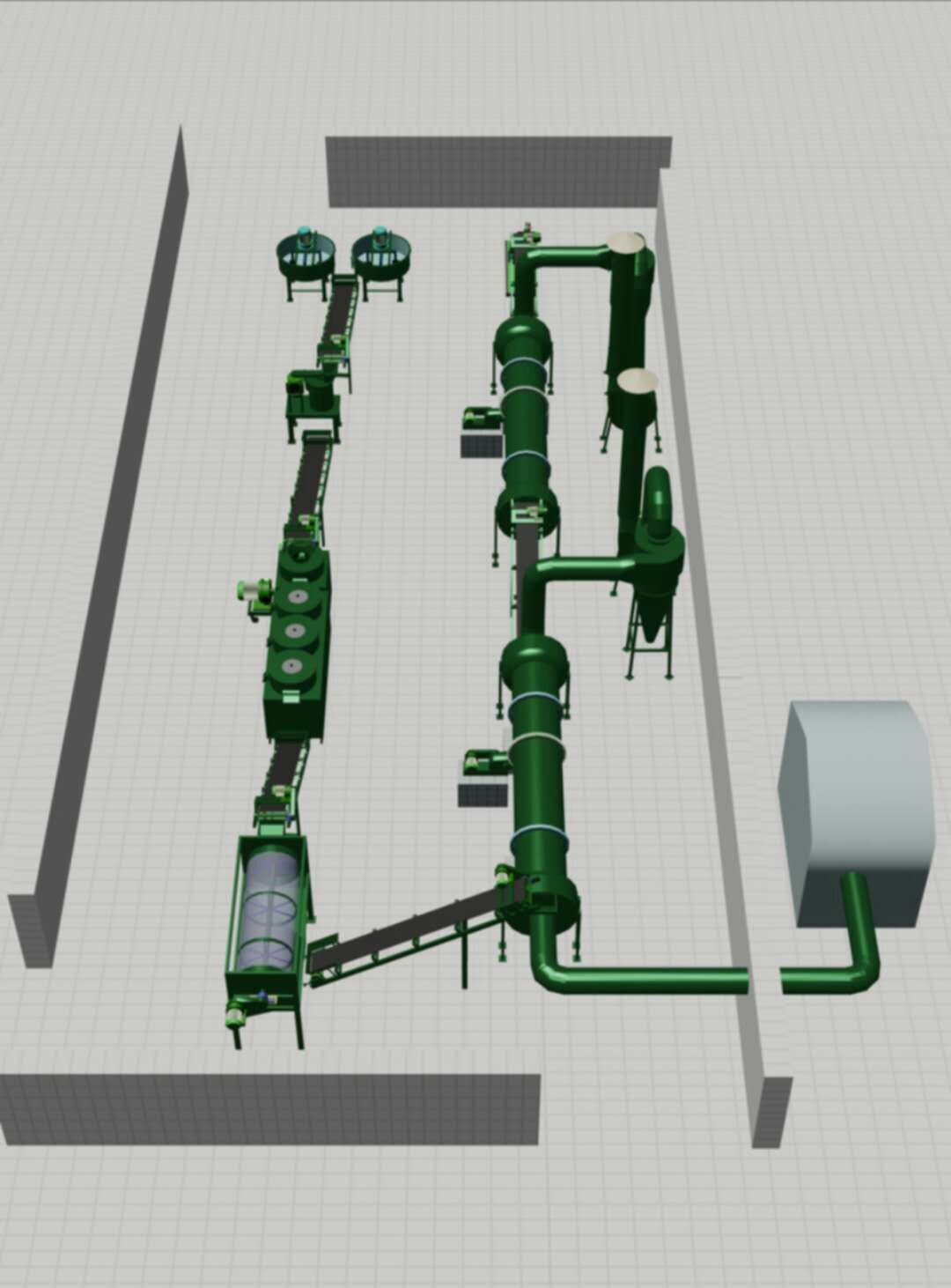

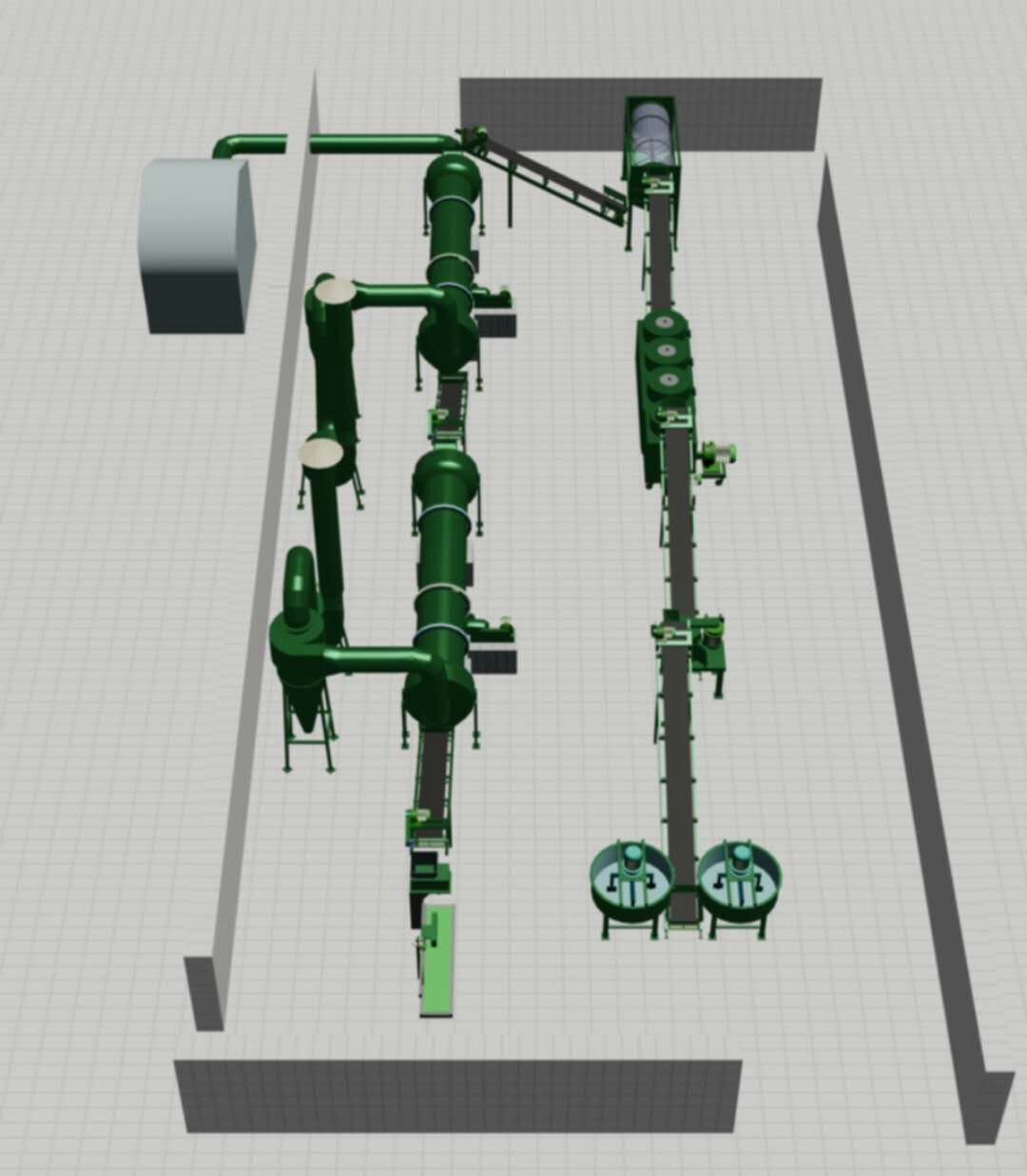

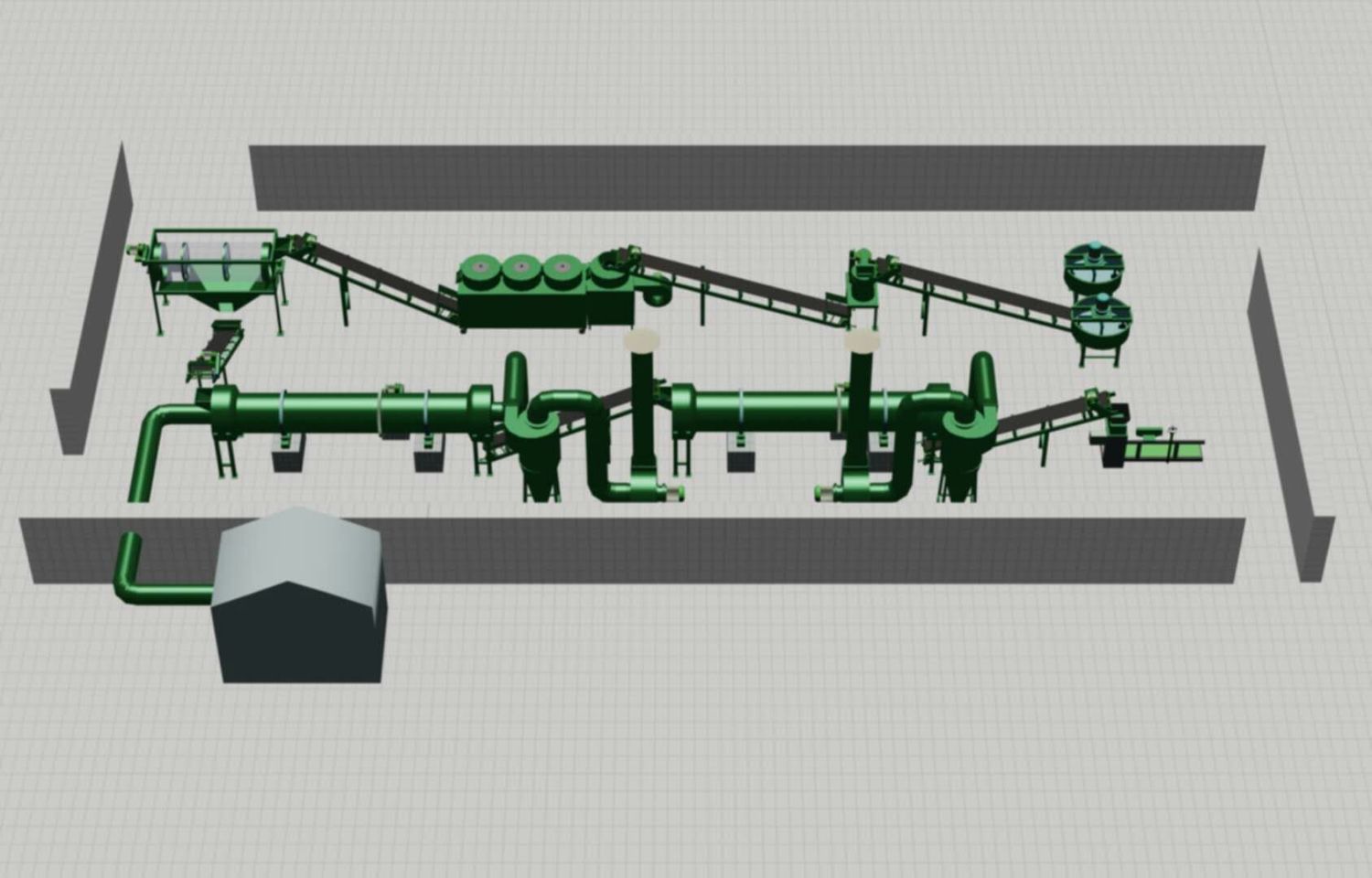

Organic Fertilizer Round Ball Granule Production Line Plant

Organic fertilizer production line is a complete set of equipment from raw materials collection to the organic fertilizer granules packing.

1) Organic materials fermentation process:

It plays the preliminary but indispensable role in the whole production line.

Two main types of compost turner are widely used to turn and mix the compost and accelerate the fermentation speed, Self-propelled compost turner and hydraulic compost turner.

2) Crushing Process:

The compost lump materials should be crushed before the granulating process. But we can leave out crushing process when the compost material is fine enough. Vertical chain crusher and double-shaft horizontal crusher, two types of crushing machine can be used to crush lump compost raw materials.

3) Mixing Process:

Two types of mixing machine are applied to mix raw materials in the fertilizer production line: Horizontal fertilizer mixing machine and Vertical fertilizer mixing machine.

4) Granulating Process:

Granulating process is the core part in this production line, so we choose the suitable model of fertilizer granulator according to customers detailed requirements. Disc granulator machine, Drum granulator machine , Shifts granulator , flat die granualtor , or ring die granulator in the market . As usual , ring die granulator can be chosen to granulate the materials evenly with highest production rate and nice final granules shape.

5) Drying Process:

When granulating, the moisture of fertilizer raw materials should be 30-35 %, and moisture will reduce about 3-5% , so the final moisture is still more than 25% after granulation process .We should dry the raw materials if the moisture is more than 25%. Rotary drum drying machine is mainly used for drying the organic fertilizer granules with a certain degree of humidity and particle size.

6) Rotary Drum Cooling Machine:

The granules will take higher temperature & humidity .The rotary drum cooling machine is used for cooling fertilizer to normal temperature as well as make fertilizer particles stronger.

7) Rotary Drum Screening Machine:

It is used to separate the granules from the large or small particles which need to be returned for the second crushing and granulating.

8) Rotary drum coating machine is used to coat the fertilizer with wax and prevent the fertilizer from sticking together.

9) The last process is packaging process: Fertilizer packaging machine can package bags quantitatively and automatically. We also need some auxiliary equipment for connection such as belt conveyor, bucket elevator, etc.

The series of granule machines can make the following raw materials into granules :

The series of granule machines can make the following raw materials into granules :

1.Agricultural waste: straw, dregs of beans, cotton dregs, rice bran,etc.

2.Animal manure: mixture of poultry litter (PL) and animal waste(AW),such as,Slaughterhouse waste,Fish market,Urine and dung of cow,Pigs,Sheep,Deer,Chicken, Ducks, Geese,Goat,earthworm cast etc.

3.Industrial waste: wine lees, vinegar residue, manioc waste, sugar scum, furfural residue,Bean cakes, Vinasse slag, Biogas residue, Fruit residue, palm oil residue etc.

4.Residues of urban rubbish or sewage treatment plants.

5.Home scrap: food waste, bones, the roots and leaves of vegetables, etc.

6.Turfs, lignite, sludge, pond sludge,Sucrose slag,starch pulp.

7.Organic materials mix with mineral materials.

Technical Parameters:

Description | KHL-600 |

Capacity: T/h | 3-5 |

Raw material moisture content % | 30-35 |

Feed material particle size (mm) | 0.3-0.5 |

Pellet. rate:% | >90 |

Voltage (V) | 380 |

Pell. dia.: mm | 3.5-5.5 |

Power: KW | 65 |

Total weight:Kg | 4000 |

Size: mm | 5500-2300-1800 |

Product Features:

Product Features:

1,Nice looking in shape, simple in structure, easy in operation and service, safe in solidity, small in volume. and light in weight etc. No special training needed and operation available through manual,

2,Robust in operating, no shut down even at full load, and separate feeding device not needed,

3,Versatile available, feed production may be arranged after manure without being idle for later half year,

4,With low energy consumption and high efficiency, equipment in medium and miniature size are quite ideal for biologic organic fertilizer, feed production plant, farming and meadow, waste water treatment plant, garbage disposal and farmers both in town and village,

Allow me to outline some key advantages of our organic fertilizer pelletizer:

1. Advanced Technology: Our machine incorporates the latest and most advanced technology, ensuring precise and consistent pellet production. It maximizes the utilization of raw materials and minimizes waste, resulting in optimal efficiency.

2. Superior Pellet Quality: The organic fertilizer pellets produced by our machine boast excellent uniformity, hardness, and durability. This ensures consistent nutrient release and absorption for enhanced crop growth and yield.

3. Versatility and Adaptability: Our machine is versatile and can process a wide range of organic materials, including plant residues, animal manure, compost, and more. It is capable of adjusting to various moisture levels, ensuring consistent pellet quality regardless of feedstock variations.

4. User-Friendly Interface: Our organic fertilizer pelletizer features a user-friendly interface, making it easy to operate and monitor. With minimal training, your team can quickly adapt to and operate the machine efficiently.

5. Cost-Effectiveness: Our machine is designed with cost-effectiveness in mind. It optimizes energy consumption, reduces maintenance requirements, and ensures long-term reliability. This translates into significant savings and a higher return on investment for your business.

At Harbin Dadi Machinery, we are committed to delivering top-notch equipment and exceptional customer service. We strive to exceed our clients' expectations, providing them with reliable and innovative solutions to meet their fertilizer production needs.

I would be delighted to provide you with further information, discuss your specific requirements, or arrange a demonstration of our organic fertilizer pelletizer. Please feel free to reach out to me at your convenience.

Thank you for your time and consideration. I look forward to the opportunity of serving you and establishing a successful business relationship.